Importance of Seals in the Hydraulic System

December 15th , 2023

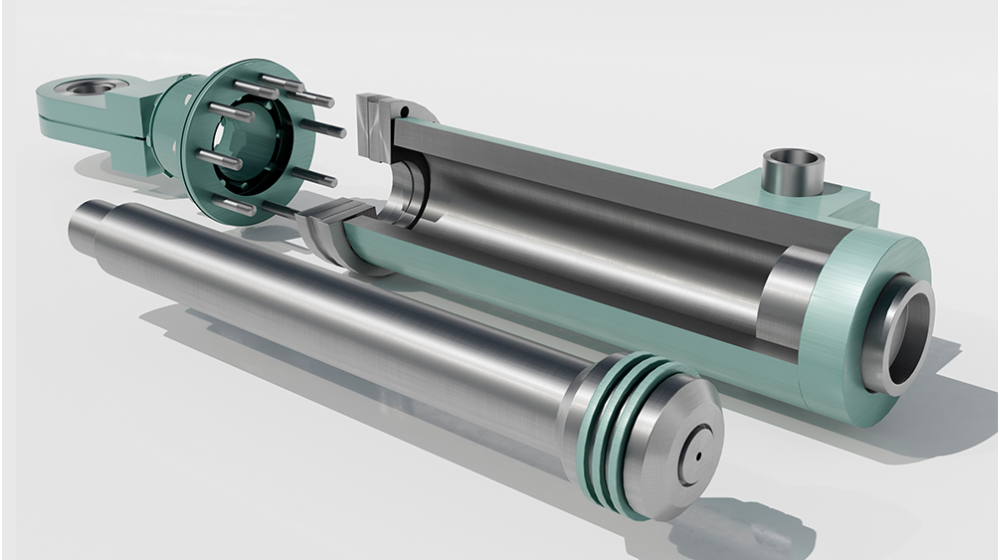

One of the most important factors influencing the hydraulic mechanism is the pressure created and maintained. The presence or creation of leaks reduces the efficiency. Integrating hydraulic seals has added value to the hydraulic system, which assembles multiple parts and components.

The fluids or the medium that is operated majorly depend on the seal-tight property. There is a chance of breaking the seal when the parts are connected. To overcome this problem, hydraulic seals are the mediums equipped at the connecting points.

Need for Sealants

The hydraulic systems have the design and functionality to transfer the fluid medium with lower viscosity. The transferring medium with high viscosity requires maximum pressure to move. The pressure involved in the process is critical to retain when the system has to function in the long run.

A minute air gap between the components can reduce the pressure created within the system. Therefore, the performance dip is the result. There are chances for breakdown and damage to the components involved.

This includes additional investment, increased operational cost, and maximum idle time. Hydraulic sealants close the air gaps and protect the system from performance dip.

Seals have become the most important secondary parts of constructing a hydraulic system.

Product Design

Every system that operates on the hydraulic principle is designed with a special provision for hydraulic seals. Seals are attached to the system from simple to complex working mechanisms for proper functioning.

Hydraulic sealants can be tailored to suit the hydraulic components perfectly. Based on the nature of the application, the seals of the materials with technical properties are selected.

Application of Hydraulic Seals

There are certain industries where the integration of hydraulic seals plays an essential role in the overall performance and effectiveness of the system.

Power transmission, oil refineries, off-highway, manufacturing, and automotive are the industries where hydraulic systems influence the end product's performance.

Various types of seals that are manufactured specifically for the industry are available in the industry.

Product Life

The hydraulic seals protect the component from short-term damage. The product life of the machine depends on every component involved in the assembly process. The malfunction in any part or component affects the entire operation.

The damages develop due to the presence of foreign substances or particles. The settlement of the composites happens when the hydraulic system is operated in the long run. The purity of the transferring medium will not be the same every time.

The clogs or dirt typically settle on the connecting points of various components. The integration of various dimensional parts may or may not create a space for the settling of dirt.

When it takes place, the dip in operational efficiency can be foreseen. The seals attached to these systems leave no space and room to settle. Therefore, the fluid medium is transferred irrespective of clogs and dirt.

Tailormade Design

The structural detailing and designing of the components in the hydraulic system are upgraded to match the requirements in terms of functionality.

Hydraulic seals can be tailored to fit perfectly with the structural design. Also, a new form of sealant that adds value to the system can be developed.

Workability

This is one of the main influential factors that makes a difference in the product ranges launched by various manufacturers.

Parker seals have been enlisted among the top-performing products in the market. It provides faster installation, reliable function, and long-lasting durability.

Hydraulic seals are available in various models suitable for incorporation into the industry's most commonly manufactured hydraulic systems.

Also, it does not react with the working condition of the transferring medium. Hence, the predefined results and productivity are ensured.

Shelf Life

Every product needs an exclusive time for maintenance. Paying attention to the shelf life of the seals used in the system is essential.

Every product has a worn-out period, so the seals must be replaced to maintain the functionality. The materials used in the manufacturing of seals determine their shelf life.

Henceforth, it varies. The product might not wear out during maintenance, but it has to be changed periodically to avoid uncertainties and sudden malfunctions.

Varying Pressure

Hydraulic seals are designed and manufactured with the fundamental expectation to deliver their purpose under varying conditions.

The seals are designed with the minimum coefficient of friction for a firm connection between the components, which is critical when varying pressures are applied.

Summary

We hope this article has provided you with valuable information. We have enriched you with insights into the importance of hydraulic seals in a system. Parker Seals are the leading branded product that fulfills customer's expectations and requirements. Arvi Hitech is the authorized distributor of Parker products in the market stocked with various models of hydraulic seals.